The KAM Difference

Safety, quality, focus, excellence, and continuous improvement are the expectations of everyone at Keselowski Advanced Manufacturing.

- High quality is providing defect-free solutions with on-time delivery to assist the success of our partners and customers.

- Focus is a priority to assure compliance to regulatory and customer requirements.

- Excellence is improving productivity over time. Opportunities are abundant and transforming these to better performance is essential to meet our goals.

- Continuous improvement is our mindset and the way we work each day by finding ways to make our performance and solutions better each day. Through this approach, we are committed to the success of our team, customers, partners and suppliers.

Learn more about our wide-ranging, industry-leading capabilities below.

Additive Metal Manufacturing

Commitment to quality is top of mind, and only state-of-the-art, advanced equipment and materials will do. Our current lineup includes:

- (5) EOS M 400-4 Quad Laser with 400W Lasers

- Build Volume: 400mm X 400mm X 400mm

- (1) EOS M 290 with 400W Laser

- Build Volume: 250mm X 250mm X 325mm

- (10) EOS M 280 with 400W Laser

- Build Volume: 250mm X 250mm X 325mm

- (1) Velo3D Sapphire XC

- Build Volume: 600mm X 550mm

- (3) SLM 280 Dual Laser with (2) 700W Lasers

- Build Volume: 280mm X 280mm X 365mm

- (1) GE Concept Laser M2 Multi-laser Machine

- Build Volume: 250mm X 250mm X 350mm

Materials

- Aluminum: AlSi10Mg, 6061-RAM2, F357, Dispal® S220 AM

- Titanium: TiAl64V, Ti6242

- Stainless Steel: 17-4, 316L, Maraging

- Inconel: 718, 625, 939

- Haynes: 282, 214

- GRCop-42

- Other materials available upon request

CNC Machining

It’s at the core of what we do, and we do it well. Our current lineup includes:

- (2) Mazak INTEGREX i-300S (7-axis)

- (2) Mazak Variaxis i-800 (5-axis)

- (1) Mazak Vertical Mill VCN-530C (4-axis)

- (1) Mazak HCN5000 Horizontal Mill (4-axis)

- (1) Mazak HC5000 Horizontal Mill (4-axis)

- (1) Mazak VTC3000KY Vertical Mill (3-axis)

- (1) Mazak QT- Primos (2-axis)

- (3) Matsuura MX-330 PC10 (5-axis)

- (1) GF Wire EDM (23.62” x 15.75” x 13.78”)

- [1] HB1200 Molybdenum Wire EDM

Advanced Simulation

KAM’s areas of expertise expand into multi-physics simulation to enhance our rapid production capabilities. The KAM engineering team’s innovative skills provide our customers unparalleled engineering competence to make sure your parts are First-Time-Right.

- FEA, Material & Topology Optimization

- Fatigue Simulation & Analysis

- Modal Analysis

- Impact analysis

- CFD Analysis, Air & Fluid Flows

- Heat Transfer Simulation, 1D & 3D

- Multi-Physics Co-Simulation

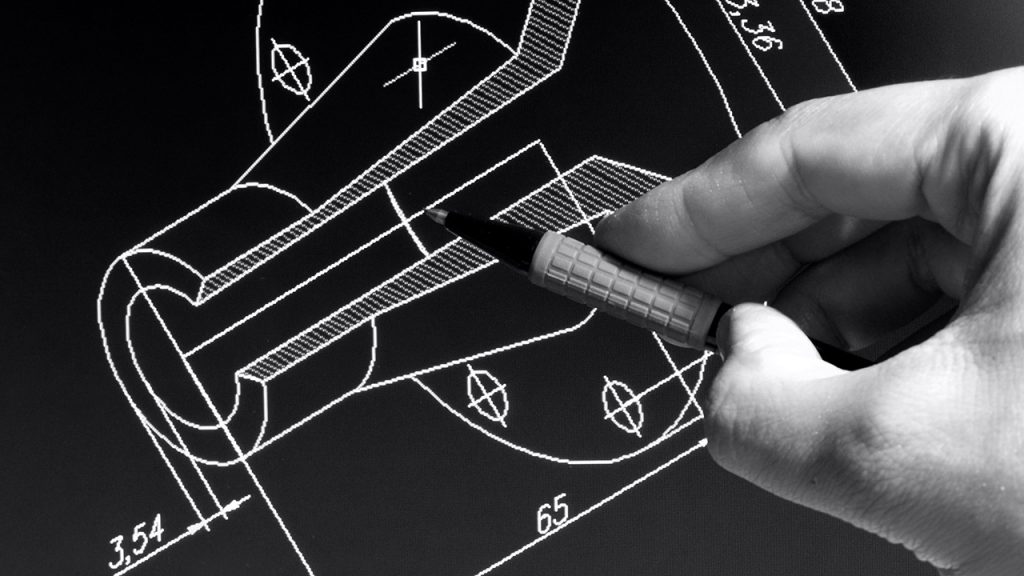

Engineering

KAM works directly with customers to understand their problems and needs. We develop and manufacture custom solutions through our state-of-the-art, collaborative engineering processes. With great attention to details, our vertically integrated in-house approach allows us to deliver speed and high-quality products and services to our customers. KAM’s process includes seamless, direct communication with our team, with a fierce commitment to overall customer service.

- Siemens NX

- SolidWorks

- Autodesk Fusion 360

- Rhino3D

- Netfabb Ultimate

- Materialise Magics

Powder Analysis

Our expert scientists conduct analysis to determine particle size, morphology, microstructure and chemical composition of powders. At KAM, we can run tests such as the light scattering technique, inductively coupled plasma atomic emission spectroscopy (ICP-OES), tap density and flowmeter testing. Additionally, our lab can perform both macro Rockwell hardness and micro Vickers and Knoop harness measurement, as well as measure for depth.

- Hall Flowmeter

- Particle Size Analyzer

- Tap Density Measurement

- Morphology Observation by 3D microscope

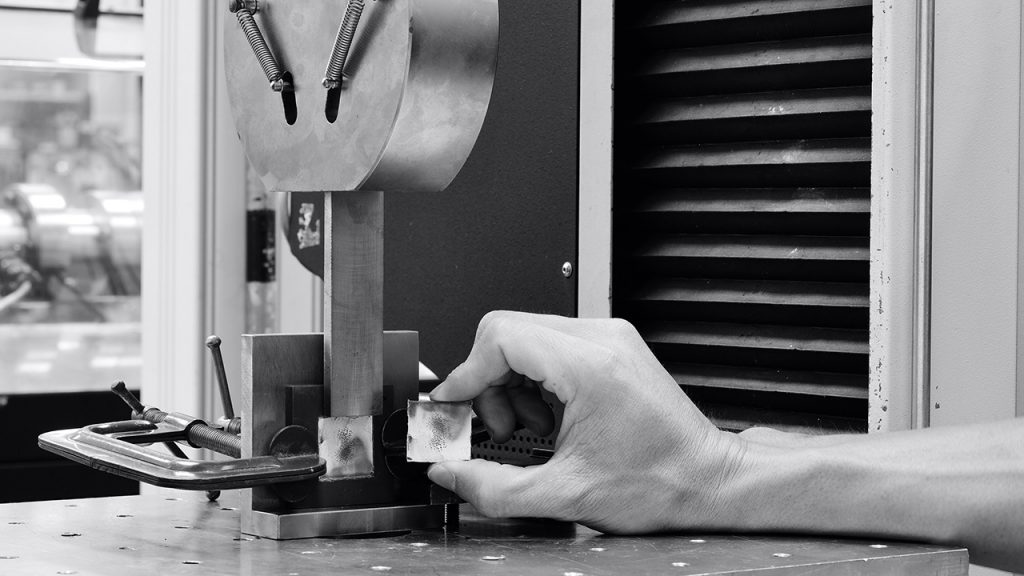

Mechanical Testing

At KAM, mechanical testing plays an integral part in ensuring we provide only the highest quality products. Within our material characterization lab, we can run the following tests: Tensile Strength, Rockwell, Fracture Toughness and Micro Hardness. We can also test for properties such as fatigue, crack propagation, creep/stress rupture.

- Universal Tester

- Hardness Tester

Post Processing

Post processing quite literally finishes the job. Our services include surface finish enhancement, stress relieving, heat treatment and any finish coatings the customer requests.

- CLM Vibe Tech Finishing Tumblers

- Keyence 3-Axis Laser Marker

- Wet Blasting and Sand Blasting

Metrology & Quality Control

We’ll check it once, then we’ll check it again. Part of the KAM Difference includes meticulous quality control and assurance. We can analyze void size and distribution, wall thickness, porosity to help determine density, part to CAD comparison, part to part comparison and first article inspection.

- Hexagon Global S CMM

- Nikon MCAX25 with ModelMaker H120 Scanner

- Pinnacle X-Ray Solutions

- Metallurgical laboratory

- Optical Comparitor

- Density Kit